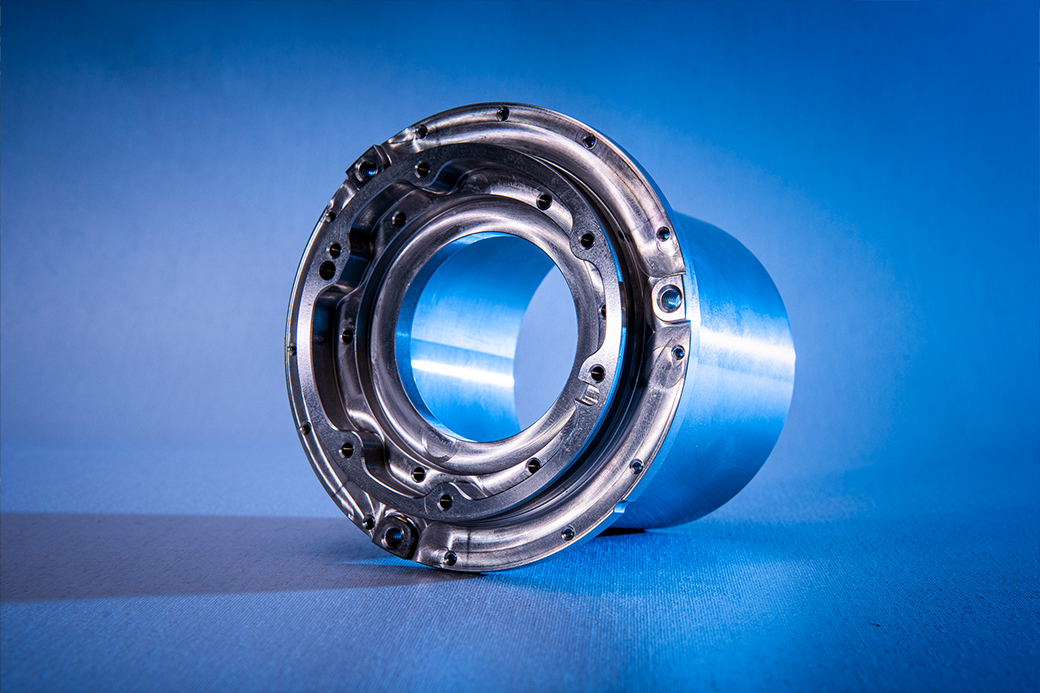

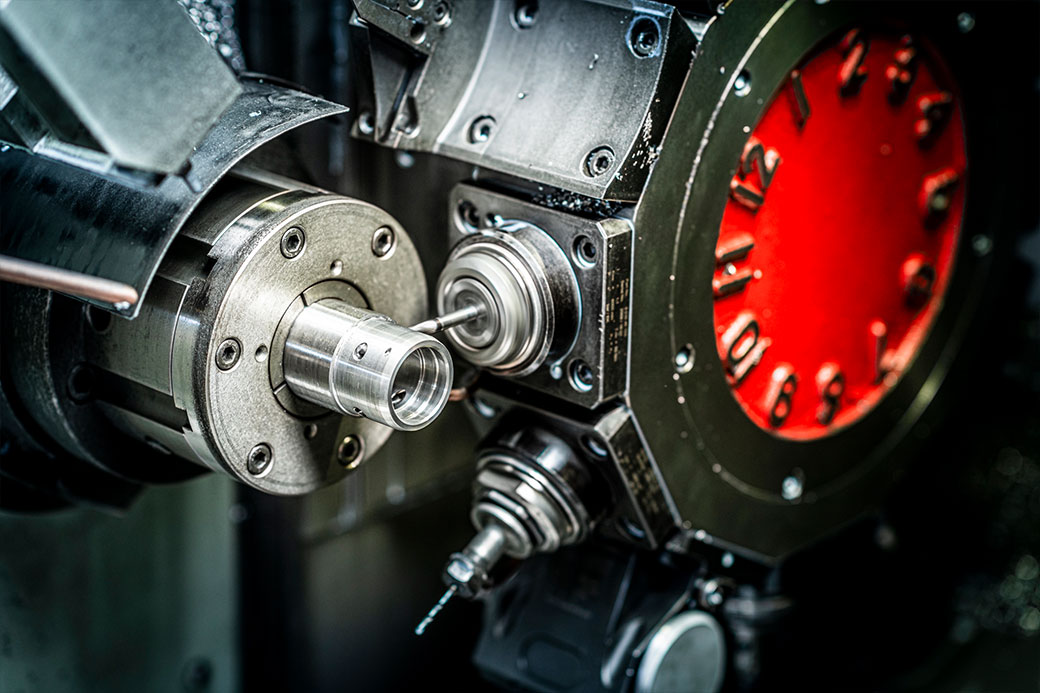

CNC draaien

CNC staat voor Computer Numerical Control, een benaming voor computergestuurde machines. Deze CNC-machines worden gebruikt om onderdelen tot op een honderdste van een millimeter nauwkeurig te draaien. Dit kan variëren van onderdelen voor verpakkingsmachines tot onderdelen voor semiconductors.

Bij ons kan je simpelweg tijd besparen, omdat we vóór, tijdens en na het productieproces met je meedenken over hoe we zo efficiënt mogelijk kunnen produceren.

Jouw belang, is ons belang!

Wil jij weten hoe Brans Metaalbewerking kostenefficiënt voor jou kan CNC-draaien? Neem dan hier contact met ons op

BIJ ONS IS DE KOFFIE ALTIJD VERS

NEEM CONTACT OP VOOR EEN AFSPRAAK

Just in time delivery CNC-draaien

Heb jij onderdelen nodig die precies op tijd afgeleverd moeten worden? Maak je geen zorgen; bij Brans Metaalbewerking begrijpen we de urgentie van een levering die geen minuut te laat mag komen. Daarom kan je bij ons een just in time delivery aanvragen.

Dit betekent concreet dat we de juiste hoeveelheid onderdelen precies op het afgesproken tijdstip afleveren op locatie. Hierdoor zullen je voorraadkosten minder worden en hoef je je niet meer druk te maken over het beheren van de voorraad.

Hoe dit precies werkt? Neem hier contact met ons op om informatie in te winnen.

Jouw voordelen

Machines, bewerkingen en materialen