Brans Metaalbewerking

Op zoek naar een betrouwbare productiepartner in CNC-frezen en draaien?

Wij zijn jouw specialist in het produceren van kleine en middelgrote series van 25 tot 10.000 stuks

BIJ ONS IS DE KOFFIE ALTIJD VERS

NEEM CONTACT OP VOOR EEN AFSPRAAK

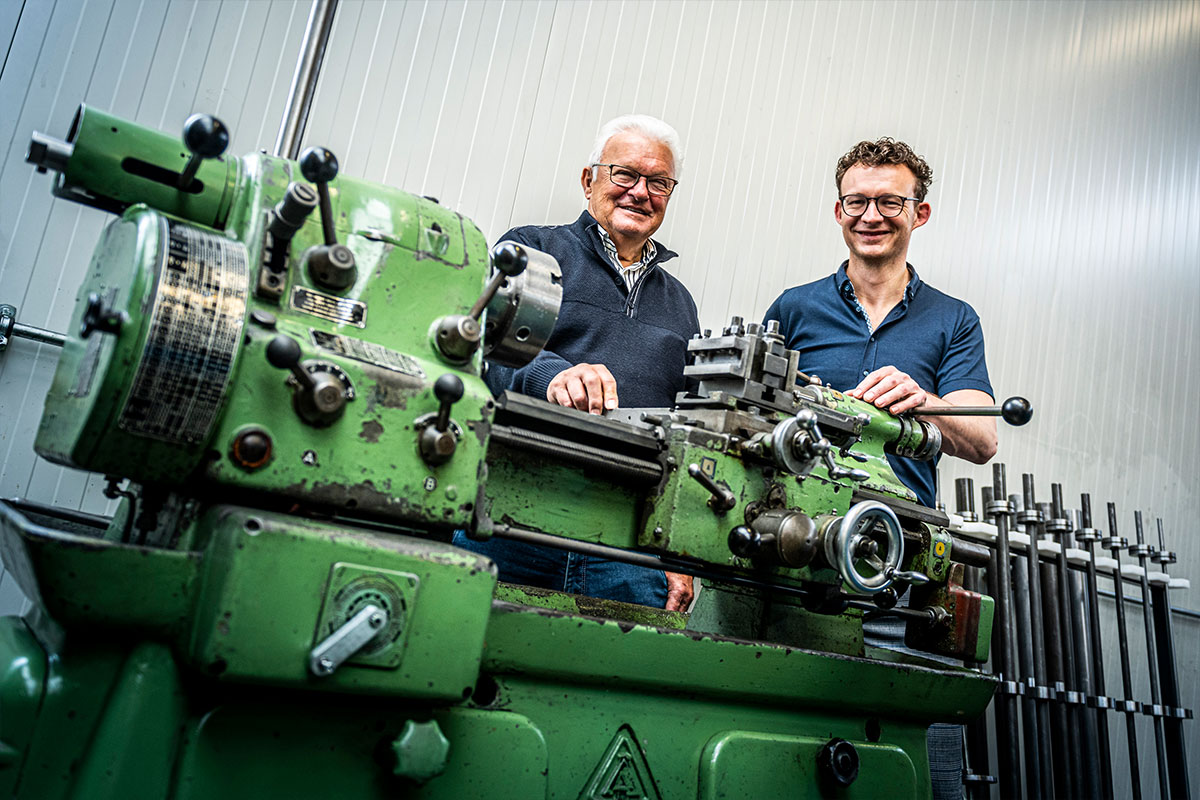

Over Brans Metaalbewerking

De metaalindustrie ontwikkelt zich voortdurend en juist dat maakt ons vakgebied zo boeiend. Zo zijn er door de jaren heen ook binnen Brans de nodige innovaties gedaan. Dit betekent een geavanceerd machinepark, een werkwijze die voortdurend wordt geoptimaliseerd en er heeft zelfs een wisseling van de wacht plaatsgevonden!

Om je een zo betrouwbaar mogelijk beeld te geven van ons familiebedrijf, hebben we een verhaal geschreven over Brans. Een verhaal waarin we terugblikken op de geschiedenis, een sfeerimpressie geven van het metaalbedrijf en een vluchtige blik werpen op de toekomst.