Fast delivery times

Just-in-time delivery, flexible delivery, fast delivery, delivery on demand…

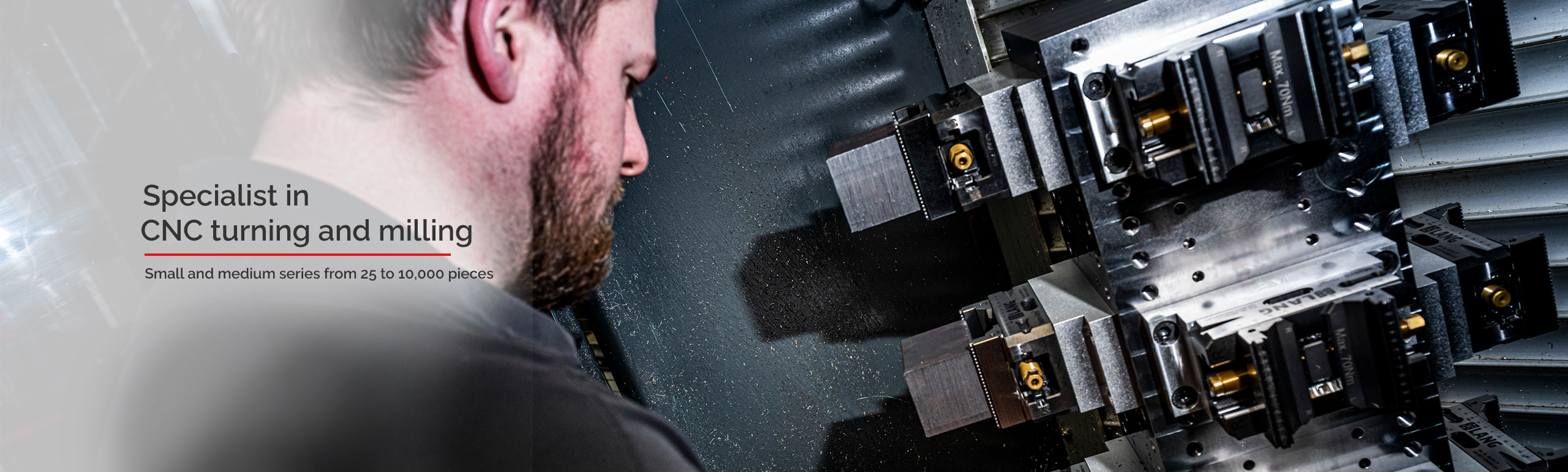

Your delivery time and requirements determine our planning. Of course, at Brans Metaalbewerking, we ensure that you always receive quality products on time. This is a precise interaction between our people and machines. Our innovative machinery plays a key role in this. It enables us to produce for you on demand, unmanned and 24/7. And thanks to our 3D visualisations, we ensure that this happens quickly, cost-effectively and without errors.

Fast delivery times

Just-in-time delivery, flexible delivery, fast delivery, delivery on demand…

Your delivery time and requirements determine our planning. Of course, at Brans Metaalbewerking, we ensure that you always receive quality products on time. This is a precise interaction between our people and machines. Our innovative machinery plays a key role in this. It enables us to produce for you on demand, unmanned and 24/7. And thanks to our 3D visualisations, we ensure that this happens quickly, cost-effectively and without errors.

Thinking partner

Cooperation, that’s what it’s all about at Brans Metalworking. We have more than 40 years of knowledge and experience in producing parts for many industries. We use this know-how to think along with you about how we can serve you best and fastest. Not only do we work entirely according to your wishes and specifications, we also relieve you of all your worries from A to Z. Many customers find our well-functioning collaboration in the pre-production process and our complete service in assembly and stock management a major added value.